RE:using Resources

The linear economy has little respect for the Earth's raw materials, as it extracts finite resources and ignores the waste that's generated.

Circular economic models are now seeking to replace this linear approach and change the underlying principles of our financial structures. In a circular economy, we look at waste not as a problem, but as a resource in the wrong place.

Discover inspiring stories and insights that demonstrate how we can design waste and pollution out of our systems by using regenerative materials and extending their lifecycles.

Prosperity Without Pollution

Instead of pollution and landfill, what if we left behind...nothing? Just as humans created the idea of waste, many are now working to deconstruct it – and using what remains to build a circular society. From fungi that breaks down construction waste to pineapple leaves that are made into natural textiles, our waste-free world is already taking shape.

Recycling Resources

Turning waste streams into reusable materials

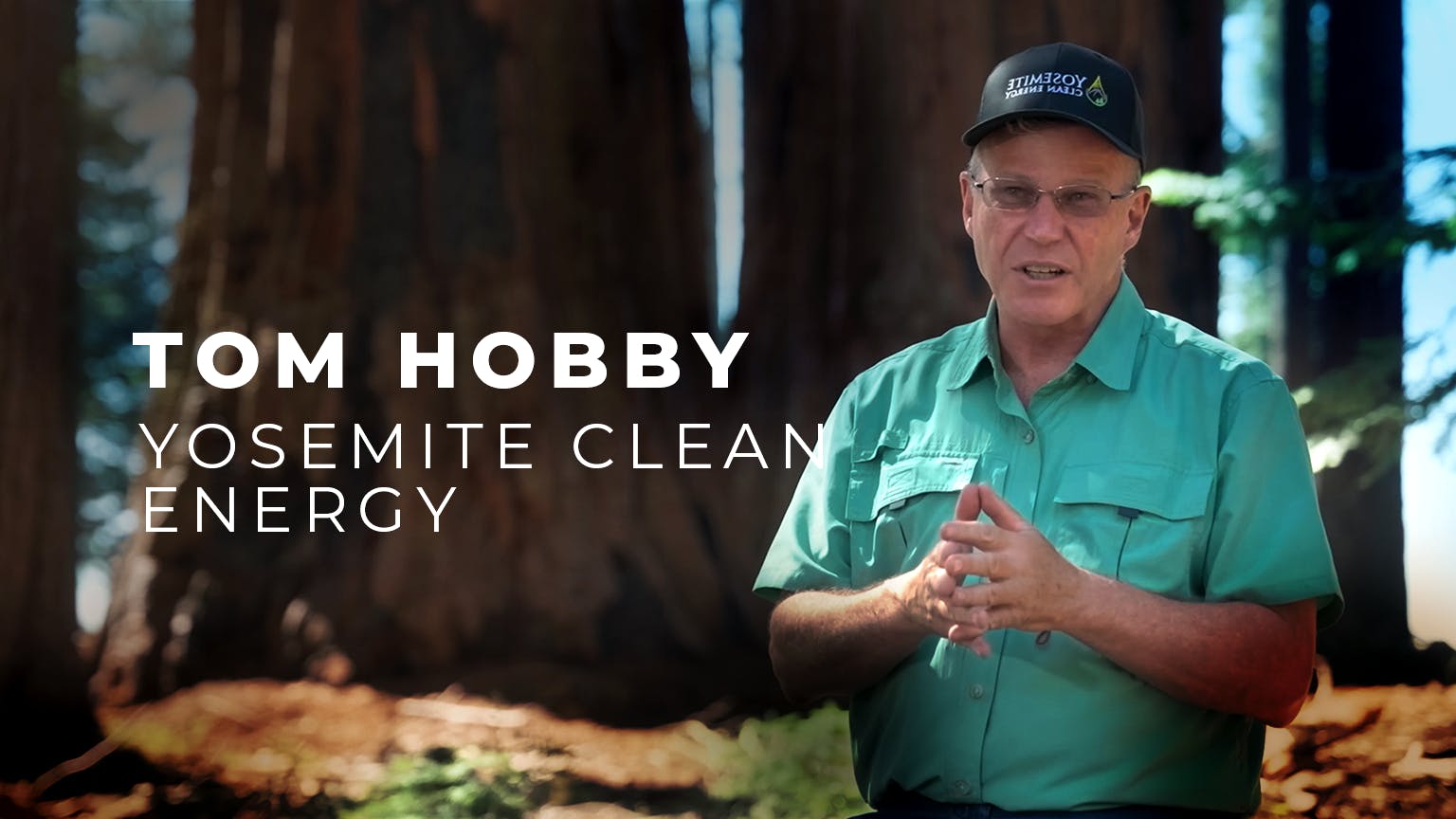

Fuel From Forest Waste

Discover how Tom Hobby's Yosemite Clean Energy deals with the excess timber created by modern forestry to transform wood waste into renewable green hydrogen and natural gas. Yosemite Clean Energy is a member of the Sustainable Markets Initiative's Hydrogen Task Force.

Eliminating Food Waste

Making the most of the food we don't eat

Recycling Waste Water

Less than half of India's population has access to clean drinking water. Absolute Water, based in New Delhi, has created a solution. Using specially-bred worms to remove micropollutants in the initial phase of filtration, Absolute Water transforms sewage waste into safe drinking water.

A Plastic-Free Future?

Innovative materials that don't cost the Earth

Circularise

Globally, less than 10% of all materials come from recycled sources, but digital passports allowing the end-to-end traceability of raw materials could change this. By operating on an open blockchain ledger, Circularise are creating transparent supply chains and accelerating a global circular economy.

Lessons In Chemistry

Harnessing natural processes to break down materials